Hand Drilling Drill Holders

I have never used a power drill and don't

plan to. They have their place but I haven't been there

yet. I think really hard, ground up sport routes couldn't

be developed without them but any moderate route or route

bolted on rappel should be hand drilled in my opinion.

That's just what I think and many people think otherwise.

If you are in a wilderness area or national park, power

drilling is illegal so there are places where a first

ascensionist must drill to use bolts. Of course there are

those who believe climbers shouldn't use bolts at all.

Anyway, I try not to drill more bolts than I need to. If a

climb can be reasonably protected without bolts, I won't

place bolts.

That said, hand drilling is hard, tiring and often frustrating work. With a poor stance and hard rock, it can easily take a half hour to hand drill and place a bolt. Also, many drill holders are annoying to use and inefficient. Some drill holders have set screws that need to be constantly tightened. Some drill holders require two tools (two wrenches or a hammer and a wrench) to change bits. Some are heavy or large. I've heard that some pinch your hand. I decided to try to make a better drill holder.

The type of drill holder that I make these days is called the bombproof because I tried to develop a holder that would last nearly forever. It is made from a high strength 7/8" bolt. Not only is the steel high strength, it is extremely tough which is apparent when I try to machine it. The bit is held in place by two set screws so one tool, an Allen wrench, is required to change bits. The grip is Shore 60A urethane that is cast in place and cannot be removed. It has an extremely hard steel striking surface - harder than the hammers. The socket is about 2.7 inches deep. I know of bombproof holder that have placed hundreds of bolts and are still going strong. I have several bombproof holders available.

Currently, all the holders come with a cord leash attached by means of a split ring. This system can be seen in the photo at the top of the page. I've tried a lot of different methods for a leash but this one is the only system that works.

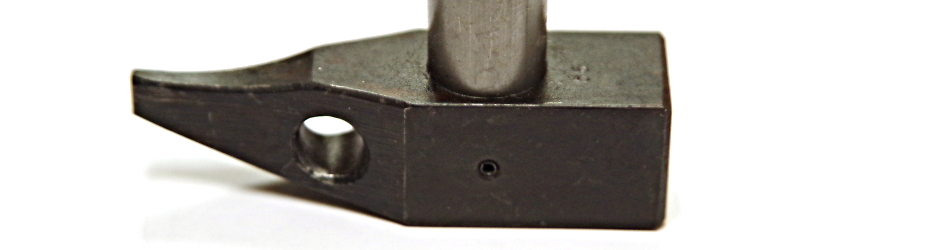

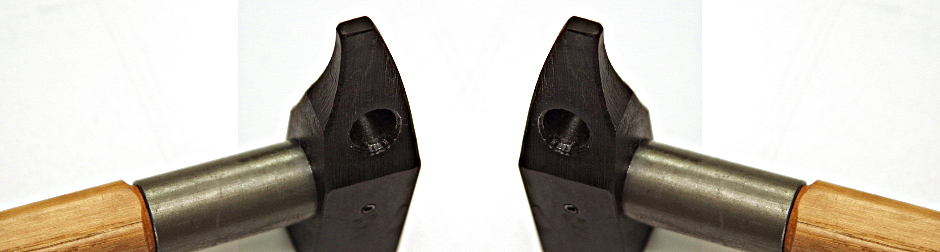

A new Bombproof holder and one that has placed hundreds

of 3/8" boltsThat said, hand drilling is hard, tiring and often frustrating work. With a poor stance and hard rock, it can easily take a half hour to hand drill and place a bolt. Also, many drill holders are annoying to use and inefficient. Some drill holders have set screws that need to be constantly tightened. Some drill holders require two tools (two wrenches or a hammer and a wrench) to change bits. Some are heavy or large. I've heard that some pinch your hand. I decided to try to make a better drill holder.

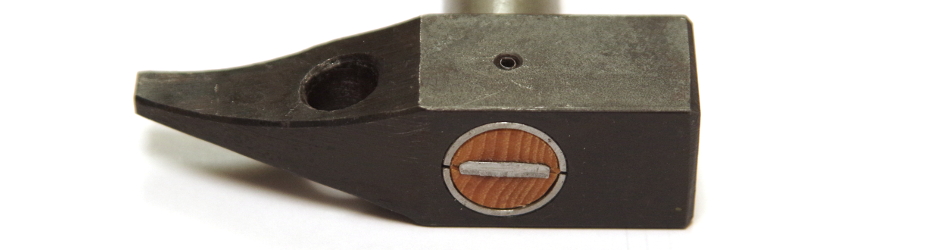

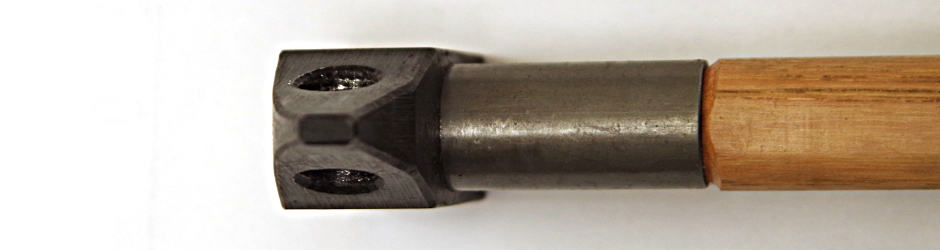

The type of drill holder that I make these days is called the bombproof because I tried to develop a holder that would last nearly forever. It is made from a high strength 7/8" bolt. Not only is the steel high strength, it is extremely tough which is apparent when I try to machine it. The bit is held in place by two set screws so one tool, an Allen wrench, is required to change bits. The grip is Shore 60A urethane that is cast in place and cannot be removed. It has an extremely hard steel striking surface - harder than the hammers. The socket is about 2.7 inches deep. I know of bombproof holder that have placed hundreds of bolts and are still going strong. I have several bombproof holders available.

Currently, all the holders come with a cord leash attached by means of a split ring. This system can be seen in the photo at the top of the page. I've tried a lot of different methods for a leash but this one is the only system that works.

A regular and short Bombproof

I have also made a few odd types of holders for various applications. I am always ready to try and make whatever it is people need or want. Below is the micro version.