The Prehistory of the DAMMERR

My climbing partner and I were in the habit of putting up

new routes and since most Sierra

routes have slabby bits, we were drilling quite a few holes

for lead protection, belays and

rappel stations. I have never used a power drill on a climb

and don't intend to so we spent

many an hour pounding away at hand drills. This is long,

tedious, hard work and we often

focused on how quickly we could get a bolt in. 10 minutes

per bolt isn't uncommon and

since a 200 foot pitch might involve 10 lead bolts and two

belay bolts you have plenty of

time to think about it.

I have tried to research the ergonomic

efficiency of hammering but besides a few goofy

studies looking at bent handles, there is nothing. I found

this surprising since a hammer

is no doubt the oldest and certainly the most fundamental of

human tools. Since I fancy

myself somewhat of an experimentalist, I decided to

experiment with hammers and see

what made the best hammer for hand drilling 3/8” bolt holes

in granitic rock.

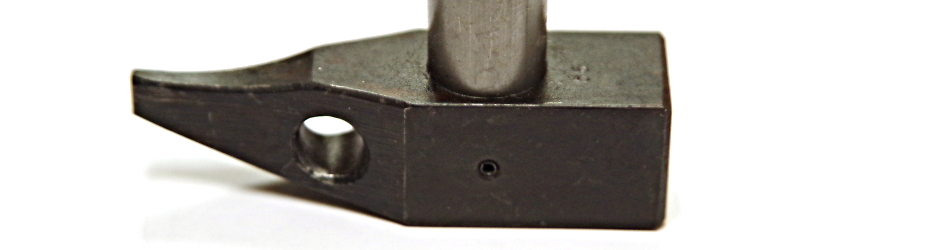

Most of the hammers marketed to rock

climbers are really piton hammers. These are

designed and intended for climbers but their primary purpose

is driving pitons rather

than drilling. Driving a piton is a very different activity

in comparison to drilling. If

somebody pounds for 10 minutes on a piton, they have

probably lost their grasp on reality.

The best piton hammer is probably the heaviest hammer you

can swing balanced against

the weight you want to carry up a climb. I don't often use

pitons and it is such a rare event

that I can make pretty much any hammer do piton service. I

wanted a drilling hammer that

can pound pitons when needed not a piton hammer that can

drill the occasional bolt.

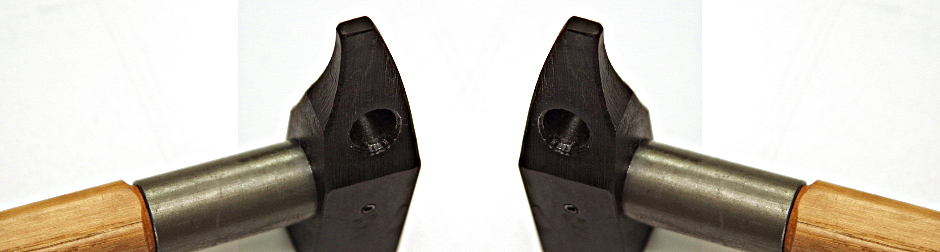

I started collecting hammers. I mostly

collected piton hammers but I also gathered a few

others that interested me. I also acquired a large block of

very good granite.

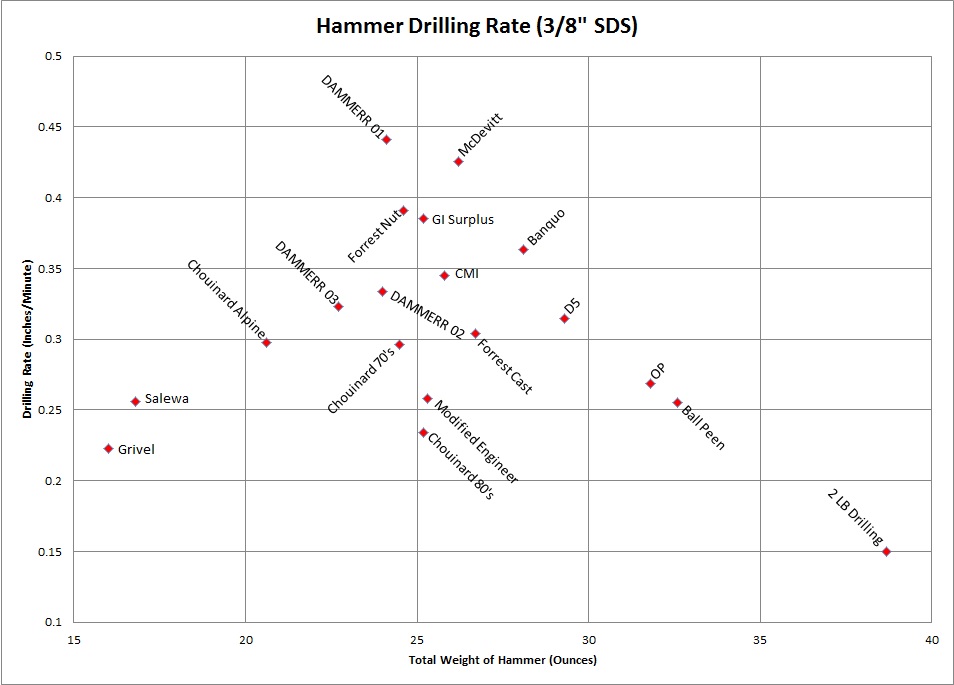

I began drilling holes in my granite block

with the various hammers keeping track of how

fast each try went. I tried to keep the drill holders and

drill bits as consistent as I could

and rested between tests so I wasn't tired.

I found that weight was the primary factor.

I quickly demonstrated that I could swing a

light hammer for a very long time without a break but the

hole didn't progress very quickly.

I also found that I simply could not continuously swing a

heavy hammer long enough to

finish a hole. There was a mid-weight hammer that seemed to

work best for me which was

about 24 or 25 ounces total weight. Most published hammer

weights are the head only and

this equates to about 16 to 17 ounces for the head which is

about the most common

hammer size, which makes sense.

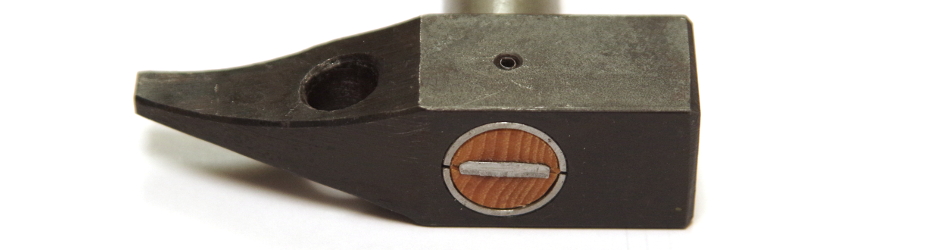

I also found that the length of the hammer

made a detectable difference and determined

that longer handles generally worked better for drilling in

the lab but a long hammer isn't

a good thing on the rock since it gets in the way when being

carried and sometimes there

isn't room on the rock to manipulate and swing a long

hammer. An overall length of 12 to

14 inches is probably a good comprise.

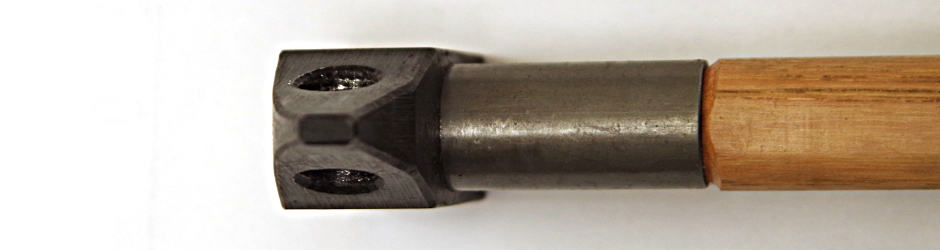

Hardness of the head is also a significant

factor. Too hard and the steel will chip and I think

the head will bounce too much not transferring enough energy

to the drill. Too soft and the

head deforms into a big mushroom and too much of the energy

is lost in deforming the

steel rather than advancing the drill bit. I think a

Rockwell C hardness of about 48 is best.

Perhaps a little bit harder.

Some of the hammers tested